Selective smoke remediation tech delivering quality outcomes

According to the Northwest Geographical Area Coordination Center (NWCC) the 2023 wildfires experienced across Oregon and Washington managed to burn through 326,273 acres and cost over 606 million dollars.

A far too regular occurrence, wineries were, once again left dealing with smoke impacted wine. For one Oregon-based winery, their 65,000 gallons of smoke impacted Pinot Noir meant that downgrading or selling the wine on the bulk market were not viable options. They needed a solution to remediate their wine in a manner that would enable them to market it as intended.

Challenge

“Since 2020, there have been a lot of learnings especially around smoke markers and the complexity of the compounds relating to smoke,” says consulting winemaker Christopher Hudson.

“At the time, reverse osmosis and carbon were the best available options. They reduced the smoke initially. However, they weren’t necessarily positioned to mitigate the smoke coming back. They also stripped a lot from the wine so when you built it back up, it never became what it was intended to be.”

“Experiencing amaea’s system, it was more advanced. The sensory outcomes were good, and I had confidence in the longevity of the treatment. This made it the best solution for treating [my client’s] wine.”

Solution

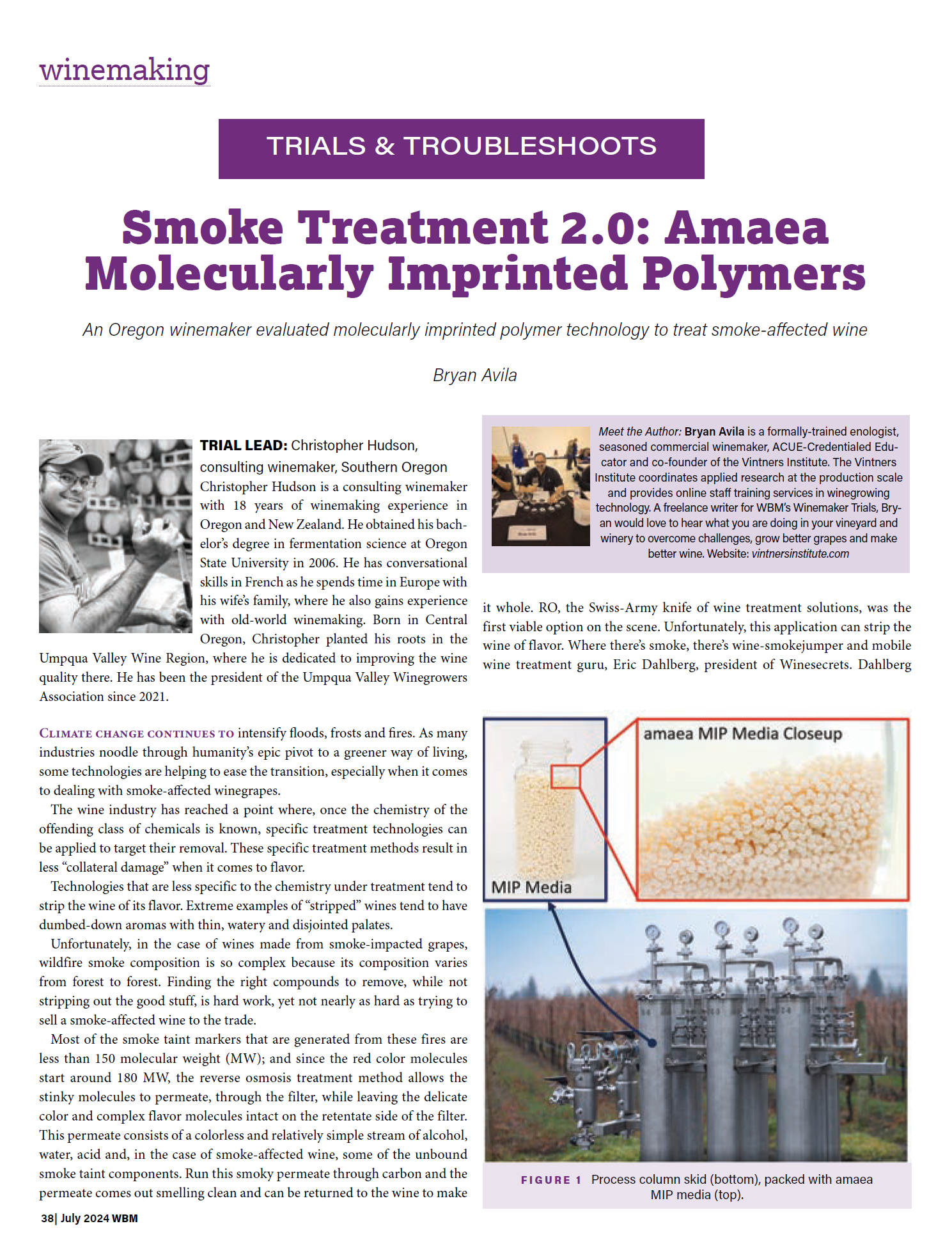

amaea VPx is a single pass, low pressure filtration system that uses molecularly imprinted polymers (MIPs) to target removing the free volatile phenols and thiophenols responsible for smoke aroma and flavor. The selectivity of the MIP treatment helps to preserve the integrity of the wine’s varietal character and body.

Approach

In determining the best solution for his client, the first step for Hudson and his team was a bench-top trial using the most severely impacted wine. Different dose and flow rates (a measure of the available capture sites and contact time of the wine with the MIPs) were applied to understand amaea VPx’s performance. The samples, including a carbon treatment, were sent to ETS Laboratories for analysis.

Comparative analysis results

Four samples sent to ETS Laboratories for analysis included:

Control

Carbon treated

amaea VPx 10/100 treated

(dose rate: 10 g/L; flow rate: 100 CV/hr)amaea VPx 15/100 treated

(dose rate: 15 g/L; flow rate: 100 CV/hr)

Smoke removal

Volatile phenol percentage change after treatment:

2023 Oregon Pinot Noir

For the amaea VPx samples, as the dose rate increased, the level of removal increased. The amaea VPx sample treated at the higher dose rate of 15 g/L and flow rate of 100 CV/hr, achieved 39-55% (50% average) removal of the volatile phenol smoke compounds with the sum of cresols reduced by 54%.

Across all smoke related analytical markers, amaea VPx at both the 10 g/L and 15 g/L dose rates, outperformed carbon which achieved an average of 17% in removal.

Being able to understand which solution would reduce smoke compounds as much as possible, while ensuring removal was below sensory thresholds provided Hudson with the insight needed to support his decision to move forward with amaea VPx.

“Most lots had 32 – 33 (μg/L) phenols and knowing we were able to reduce it to around 15 (μg/L) using amaea VPx meant we were in the right place. The dose and flow rate data helped us understand our starting point when we moved to the commercial unit,” says Hudson.

Selectivity

Sensory overview after amaea VPx treatment

(color, mouthfeel, smoke)

The total cresols removed, when averaged across the two amaea VPx treatments, was 46%. The total anthocyanins reduced by only 8% showing the treatments had marginal impact on color. The 25% impact on tannins was reflective of the heavy concentrations due to the high level of smoke impact and the heavy level of treatment required. The overall selectivity of the system mirrored the observations made during tastings where a quality enhancement and retention of the mid-palate was noted.

“The trial helped us determine where to start. Every lot had its own differences and therefore required slightly different treatment rates. When we were on the commercial unit, we had the tank-side flexibility to conduct real-time tastings and adjust accordingly.”

“For each tank, at 3,000 gallons we would taste, dial in and set the direction for the remaining 17,000 gallons. We customized as required to confidently remove the cresols and impacts without deteriorating the wine quality,” says Hudson.

Commercial treatment results

Sensory

“Using amaea VPx reflected a quality level change which traditional systems generally stripped out. The mid-palate was maintained, and the flexibility of the system enabled us to achieve the levels needed throughout the treatment,” says Hudson. “The treatment also showed stability which provided confidence in its longevity.”

Smoke remediation analysis

Volatile phenol percentage change after amaea VPx treatment (≈15 g/L @ 75 CV/hr)

Decrease in volatile phenols after amaea VPx treatment

(≈15 g/L @ 75 CV/hr)

“According to the ETS data, the treated wine was in the ballpark of a 35% reduction of smoke-affected markers. It was convincing and we are happy with the outcome,” says Hudson.

Operational gains and waste stream reduction

“If I’d gone down a different path it would have been multi-step, and my bins would have been full. Using amaea’s system, it was single pass, there was minimal waste, and we didn’t need to re-build the wine,” says Hudson.

Conclusion

“So much work goes into wine and seeing it literally going up in smoke isn’t where you want to be. You want to maintain the wine’s quality to the best of your advantage, to the level you know it should be hitting the market,” says Hudson.

“Knowing there are tools out there as opposed to sending it down the drain is great, and, with amaea, you are getting the most innovative solution currently available.”

Treatment summary

Wine varietal: 2023 Oregon Pinot Noir

Volume of wine processed: 65,000 gallons

Date of treatment: April 2024

Applied dose rate: 10 – 15 g/L

Applied flow rate: 75 - 100 CV/hr

Treatment conducted by: Winesecrets

amaea solution: amaea VPx

About Christopher Hudson

Christopher Hudson is a consulting winemaker with 18 years of winemaking experience in Oregon and New Zealand. He obtained his Bachelor of Fermentation Science at Oregon State University in 2006. Born in Central Oregon, Christopher planted his roots in the Umpqua Valley Wine Region, where he is dedicated to improving the wine quality there. He has been the president of the Umpqua Valley Winegrowers Association since 2021.

Discover more

Bryan Avila from Wine Business Monthly sat down with Christopher Hudson to discuss and share their thoughts on amaea VPx and Hudson’s application of the technology.